-

Posts

6,425 -

Joined

-

Last visited

Reputation Activity

-

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel is now cut back to decent metal, revealing rust which had crept between the layers of the lip.

Before cleaning it up I welded the marks from the spot weld drill. I wanted to make sure the metal was full thickness so when it comes to welding the layers together I can crank up the current without risking blowing through.

It took a while to remove the rust, as it had pitted quite deeply in places.

There's a little bit of light rusting on the inside, which I've treated with phosphoric acid to hopefully stop it getting worse. I'll inject with cavity wax after welding, obviously.

One casualty was the angle grinder I use for knot wheeling - only a cheap one so really a disposable item.

-

mat_the_cat got a reaction from Lacquer Peel in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Lacquer Peel in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel is now cut back to decent metal, revealing rust which had crept between the layers of the lip.

Before cleaning it up I welded the marks from the spot weld drill. I wanted to make sure the metal was full thickness so when it comes to welding the layers together I can crank up the current without risking blowing through.

It took a while to remove the rust, as it had pitted quite deeply in places.

There's a little bit of light rusting on the inside, which I've treated with phosphoric acid to hopefully stop it getting worse. I'll inject with cavity wax after welding, obviously.

One casualty was the angle grinder I use for knot wheeling - only a cheap one so really a disposable item.

-

mat_the_cat got a reaction from Turbowomble in 205 GTi - repairs underway

mat_the_cat got a reaction from Turbowomble in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

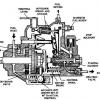

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from Coprolalia in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Coprolalia in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel is now cut back to decent metal, revealing rust which had crept between the layers of the lip.

Before cleaning it up I welded the marks from the spot weld drill. I wanted to make sure the metal was full thickness so when it comes to welding the layers together I can crank up the current without risking blowing through.

It took a while to remove the rust, as it had pitted quite deeply in places.

There's a little bit of light rusting on the inside, which I've treated with phosphoric acid to hopefully stop it getting worse. I'll inject with cavity wax after welding, obviously.

One casualty was the angle grinder I use for knot wheeling - only a cheap one so really a disposable item.

-

mat_the_cat got a reaction from Scruffy Bodger in 205 GTi - repairs underway

mat_the_cat got a reaction from Scruffy Bodger in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from LightBulbFun in 205 GTi - repairs underway

mat_the_cat got a reaction from LightBulbFun in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from RayMK in 205 GTi - repairs underway

mat_the_cat got a reaction from RayMK in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from Jenson Velcro in 205 GTi - repairs underway

mat_the_cat got a reaction from Jenson Velcro in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

I know I suggested recreating the photo, but this wasn't what I had in mind!

(On the way back from a Cars & Coffee meet, on only its second trip out!)

-

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

I've had a go at the rear calipers, and unfortunately one is beyond repair. The bleed screw has seemingly been hammered into the body, and after a good while welding things to that and the remains of the flexi, they both came free (yay!) but the threads were non-existent (boo). I drilled out and re-tapped larger, but it turned out the body was cracked

The better one of the two is pictured above, and that was savable. I dunked the steel part of the body in Deox C, along with various other brackets.

It took several days to remove all the rust!

Before a coat of galvanising primer.

I've never rebuilt a caliper with integral handbrake mechanism before, so had to make up a tool from an old socket to compress everything to reassemble.

The last part was fitting a new piston, which is where things went less well. It was the wrong size, and too small to seal in the bore. Double checking sizes and the 205 uses a 30mm piston, however the 206 uses a 32mm piston which looks to be what we have. I'd already bought another 205 caliper to replace the cracked one, but wouldn't match the one I was repairing.

Still, I thought I may as well finish the repair and see if I can sell to recoup the costs of the kit. New piston going in:

And the finished job.

Surely worth £30 to someone?

-

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

Fuel pipes are now replaced, and I've had to replicate the pipe sticking straight up out of the tank, as for some reason it's been modified to clamp to the pipe inside the tank. I plan to fit a right angle coupling at the top however.

There's a few bodges I'm finding on this, such as the battery clamp being a thin piece of bent metal, a penny washer and a UNF bolt in an M6 hole.

It was so flimsy the battery was flopping about all over the place! Now replaced with the proper clamp.

Next was the handbrake cables, should be a nice easy job until I noticed a drip from one of the rear drums.

Wait a minute...drums on a 1.9? Well yes, when she bought it the owner pointed out it was originally a 1.6, but they'd been gradually replacing all the bits to turn it into a 1.9. They'd bought the correct rear beam for it, complete with brake calipers although it looked like it'd been sitting at the bottom of the sea. So the plan was always to rebuild that at leisure, and swap it over at the same time as changing the front struts to restore the correct ride height.

So with the rear end, I'm just going to to the bare minimum to make it functional, and swap the whole thing over in the summer. I have to admit I sometimes reuse the staked nuts if the the groove falls in a different spot on the nut. But I think this one has been reused one too many times! Especially when I levered it away and it just crumbled off.

Both new handbrake cables are now on, and I'm just waiting for a new cylinder...under £10 delivered so not a big problem.

While I was there I coated everything with Lanoguard, to keep moisture away. Really impressed with the overall condition, despite the bodges!

-

mat_the_cat reacted to Joey spud in 205 GTi - repairs underway

mat_the_cat reacted to Joey spud in 205 GTi - repairs underway

I used to work for a Peugeot Talbot dealer in Rochester in the late eighties and would carry out pre delivery inspections on these honey's which would include a spirited road test up City way and Horsted road then onto the M2 roundabout at junction 3 and back again and honestly not wishing to rock the boat here but I always thought the 309Gti was a far nicer car to actually live with as a daily sorry...

-

mat_the_cat got a reaction from rainagain in 205 GTi - repairs underway

mat_the_cat got a reaction from rainagain in 205 GTi - repairs underway

Back in 2000, I bought @Puglet a Pioneer radio as a birthday present, which she fitted to her 205 XS, This was bought partly for the sound quality, but also because the display showed swimming dolphins It was transferred to the next car, a Renault Megane Coupe, and the MINI after that.

Unfortunately, an iPod adapter interface was bought which came with a reversed polarity lead, and this fed +12 V through the ground connection on the expansion socket, taking out the button illumination

This has sat for the last 10 years, so with the need for a radio again I downloaded the wiring diagram and did some probing. There was no illumination supply to the front panel so not just a case of a new front. The transistor which switched the supply was open circuit, so that was the first replacement but no joy.

Time to delve further in the circuit, and I found a couple of zener diodes which didn’t measure right.

(Circled, with the new transistor already in place)

These were a low noise type of quite a tight tolerance, which I couldn’t find exact replacements for. Eventually I managed to find some low noise types with a slightly different voltage, but with wider tolerance bands (5.2 to 6 V and 9.4 to 10.6 V). I needed 5.5 to 5.8 V and 9.5 to 9.9 V, so I just bought 10 of each and measured them until I found ones which were close to the middle of the original spec.

I soldered them in, and then re-applied lacquer to the PCB as was originally done.

Then a bit of fiddly reassembly.

And the end result?

Yay, the dolphins are back! (I confess I had tested it before reassembly and fitting though!)

-

mat_the_cat got a reaction from rainagain in 205 GTi - repairs underway

mat_the_cat got a reaction from rainagain in 205 GTi - repairs underway

Another door pocket was duly purchased and fitted, although I forgot to photo it. Puzzlingly, it came with two extra gear knobs - one new reproduction type of the incorrect BE1 shift pattern...

...and what I assume to be the original, cracked one seeing as there was a correct reproduction knob actually fitted.

The originals in good condition are rather rare, so the obvious thing to do was to make one good knob from the two.

Onto the mechanical side, and I took a look at the alternator which was only outputting around 12.7 volts. The brushes looked well used, so for £20 was worth a try for a brush and regulator pack. Comparing the two side by side:

And easily fitted with the alternator in-situ.

Unfortunately, absolutely no change in the output, so back to the drawing board 😞

Also on the list to do was the brake servo, fuel filter, and the remaining fuel hoses. I made a start by removing the old parts, and noticed something strange with the wiring. Three wires from the main loom came to a point and just appeared to have been cut.

I'd already removed the sleeving, as it was in pretty ropey condition!

From the 3 wires, there's one heavy current wire (blue), a smaller wire (orange) and an earth (green & yellow). The only possible clue is that there's something in the history about a fuel pump wiring mod, so wonder if this was something no longer deemed required. Certainly everything seems to function, so have just taped them up for now and replaced the sleeving.

I've got the new servo ready to fit, but seeing as the cambelt also needs changing I think I'll hold back for now to give a bit more access, not that I remember it being all that difficult although it has been 20 years since I last did one! (Certainly more space than on the 16v engine...)

-

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

mat_the_cat got a reaction from Joey spud in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from wesacosa in 205 GTi - repairs underway

mat_the_cat got a reaction from wesacosa in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from GeorgeB in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from GeorgeB in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel is now cut back to decent metal, revealing rust which had crept between the layers of the lip.

Before cleaning it up I welded the marks from the spot weld drill. I wanted to make sure the metal was full thickness so when it comes to welding the layers together I can crank up the current without risking blowing through.

It took a while to remove the rust, as it had pitted quite deeply in places.

There's a little bit of light rusting on the inside, which I've treated with phosphoric acid to hopefully stop it getting worse. I'll inject with cavity wax after welding, obviously.

One casualty was the angle grinder I use for knot wheeling - only a cheap one so really a disposable item.

-

mat_the_cat got a reaction from JakeT in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from JakeT in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel is now cut back to decent metal, revealing rust which had crept between the layers of the lip.

Before cleaning it up I welded the marks from the spot weld drill. I wanted to make sure the metal was full thickness so when it comes to welding the layers together I can crank up the current without risking blowing through.

It took a while to remove the rust, as it had pitted quite deeply in places.

There's a little bit of light rusting on the inside, which I've treated with phosphoric acid to hopefully stop it getting worse. I'll inject with cavity wax after welding, obviously.

One casualty was the angle grinder I use for knot wheeling - only a cheap one so really a disposable item.

-

mat_the_cat got a reaction from Dyslexic Viking in 205 GTi - repairs underway

mat_the_cat got a reaction from Dyslexic Viking in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

Back in 2000, I bought @Puglet a Pioneer radio as a birthday present, which she fitted to her 205 XS, This was bought partly for the sound quality, but also because the display showed swimming dolphins It was transferred to the next car, a Renault Megane Coupe, and the MINI after that.

Unfortunately, an iPod adapter interface was bought which came with a reversed polarity lead, and this fed +12 V through the ground connection on the expansion socket, taking out the button illumination

This has sat for the last 10 years, so with the need for a radio again I downloaded the wiring diagram and did some probing. There was no illumination supply to the front panel so not just a case of a new front. The transistor which switched the supply was open circuit, so that was the first replacement but no joy.

Time to delve further in the circuit, and I found a couple of zener diodes which didn’t measure right.

(Circled, with the new transistor already in place)

These were a low noise type of quite a tight tolerance, which I couldn’t find exact replacements for. Eventually I managed to find some low noise types with a slightly different voltage, but with wider tolerance bands (5.2 to 6 V and 9.4 to 10.6 V). I needed 5.5 to 5.8 V and 9.5 to 9.9 V, so I just bought 10 of each and measured them until I found ones which were close to the middle of the original spec.

I soldered them in, and then re-applied lacquer to the PCB as was originally done.

Then a bit of fiddly reassembly.

And the end result?

Yay, the dolphins are back! (I confess I had tested it before reassembly and fitting though!)

-

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from MorrisItalSLX in 205 GTi - repairs underway

mat_the_cat got a reaction from MorrisItalSLX in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

One of those jobs, albeit minor, was to tidy up the wiring.

I don't know who did this, or why (but I will look for you, I *will* find you, and I will kill you )

Although in reality I'll just use a particular set of skills to do a neater job. First soldered the wires together, then insulated them with glue-lined heat shink.

Then another piece of heat shrink over the whole lot, and job done.

-

mat_the_cat got a reaction from Puglet in 205 GTi - repairs underway

mat_the_cat got a reaction from Puglet in 205 GTi - repairs underway

The idle speed problem was a really simple fix! The throttle return spring, for some reason, was pushing on the wrong part of the quadrant so minimal tension when shut.

This is just an internet photo, but it was around 90° too slack, pushing on the circled moulding rather than where it should be.

To celebrate @Puglet took it out for a drive this evening, once the tourist traffic had died down.

Looking rather nice! (ATCNBE...)

Another job off the list!

-

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

mat_the_cat got a reaction from coachie in 205 GTi - repairs underway

We dropped off a vehicle at my local garage recently, and my wife happened to spot this awaiting work in their yard...

I enquired about it, and turns out it's in for a few jobs before sale. Started out life in Cyprus, and has had long periods of dry storage over here so the shell is very good - better than the ones she had when they were 10 years old.

It's also had a documented engine rebuild from a specialist, who she's been in touch with to confirm. The garage put it up on their ramp so we could check it over today, and although not perfect, it only seems to be minor stuff.

One trackrod end and lower ball joint

CV joint

Fuel hoses

Temperature gauge inoperative and high idle when warm (I think seperate sensors so possibly not linked)

Sticking handbrake cables

Low alternator output

Coolant level sensor telling lies

Missing jack

Missing door pocket but otherwise great condition interior.

I know most will just say get it bought, but any sober voices of reason out there to say why not? £7.5k which although is a lot, now seems towards the cheaper end of the range. And I'd rather be changing suspension and brakes than welding a rotten shell!