-

Posts

6,428 -

Joined

-

Last visited

Reputation Activity

-

mat_the_cat got a reaction from mercedade in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from mercedade in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from mercedade in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from mercedade in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from Asimo in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Asimo in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from groovylee in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from groovylee in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from RoverFolkUs in The grumpy thread

mat_the_cat got a reaction from RoverFolkUs in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from Mrcento in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Mrcento in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

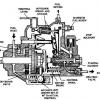

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from JMotor in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel is now cut back to decent metal, revealing rust which had crept between the layers of the lip.

Before cleaning it up I welded the marks from the spot weld drill. I wanted to make sure the metal was full thickness so when it comes to welding the layers together I can crank up the current without risking blowing through.

It took a while to remove the rust, as it had pitted quite deeply in places.

There's a little bit of light rusting on the inside, which I've treated with phosphoric acid to hopefully stop it getting worse. I'll inject with cavity wax after welding, obviously.

One casualty was the angle grinder I use for knot wheeling - only a cheap one so really a disposable item.

-

mat_the_cat got a reaction from GeorgeB in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from GeorgeB in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from RayMK in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from RayMK in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

The inner panel repair is now complete.

So I then made a couple of holes in it! Just so I could inject some cavity wax into it, as it's far easier to do it from above - and it also is so penetrative, it highlights any pinholes in the welding.

I've hacked up my new panel, and sat it in the correct position...

...before beginning the slow process of trimming to match what I've cut feom the van.

-

mat_the_cat got a reaction from Asimo in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Asimo in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from Tickman in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Tickman in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from mercedade in The grumpy thread

mat_the_cat got a reaction from mercedade in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from Coprolalia in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Coprolalia in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from juular in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from juular in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from GeorgeB in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from GeorgeB in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from Sunny Jim in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

mat_the_cat got a reaction from Sunny Jim in What has two seats, a mid-mounted 6 cylinder engine, and a turbo? Time for windscreen number 5!

Work on this has slowed slightly for two reasons. Firstly we are now having guests staying in the Airstream, and I don't think they would appreciate angle grinding during their stay. And secondly my welder had failed again!

A different fault, but I traced it to the new board I'd been sent. I contacted the supplier, rather expecting them to suggest that another fault in the welder must have damaged their replacement board. But fortunately they sent a replacement out to me but agreed it was rather puzzling.

To my surprise the next day two arrived!! They decided to send two from different batches just in case there was a more widespread issue and i suffered another premature failure. Over and above as far as I'm concerned.

Back to the van and I actually managed to do a better job than expected in curving the inner repair section.

I started by cutting a few slots in it, but when I started flattening out the 90 degree angle to match the original, found it naturally started curving in the right direction! I drilled out to match the position of the original spot welds...

...and have begun the steady process of welding it all into position.

I did bite the bullet and go for a new panel in the end - I think this will enable me to do a neater repair and hopefully avoid needing to use filler. It's still a zinc coated panel so should be better at resisting rust, even if not hot-dip galvanised as the inner layer now is.

-

mat_the_cat got a reaction from brownnova in The grumpy thread

mat_the_cat got a reaction from brownnova in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from Lacquer Peel in The grumpy thread

mat_the_cat got a reaction from Lacquer Peel in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from DavieW in The grumpy thread

mat_the_cat got a reaction from DavieW in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from Rightnider in The grumpy thread

mat_the_cat got a reaction from Rightnider in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from Sunny Jim in The grumpy thread

mat_the_cat got a reaction from Sunny Jim in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from Wibble in The grumpy thread

mat_the_cat got a reaction from Wibble in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.

-

mat_the_cat got a reaction from wuvvum in The grumpy thread

mat_the_cat got a reaction from wuvvum in The grumpy thread

Scammers reaching a new low today:

Someone my wife knew has recently died - https://www.bbc.co.uk/news/uk-wales-68435343

So she gets an invite to his funeral online, but the website wants card details to verify identity, but that no payment will be taken. Next thing is she's getting a call from the HSBC fraud department saying that the scammers are trying to take money! I'm guessing they must trawl social media for people who've died, and then go after the friends and relatives.