-

Posts

9,413 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Events

Everything posted by Zelandeth

-

That's what I've got on TPA. Mainly because they were readily available, cheap and looked appropriate. Sure they're not the best thing out there but they're entirely adequate for a small and light car. I do have some concerns about there being any solid structure left to this to anchor repairs to, and I'm generally all for giving it a go. It just looks precariously close to snapping in half from the state of the sills.

-

Those rear springs look suspiciously similar to the ones from an Estelle too...which I remember thinking looked absolutely absurdly long the first time I crawled under the back of one.

-

One I've not spotted before spotted today. Old Alexander PS bodied bus, guessing from a combination of statistical likelihood and noise that it's a B10M underneath. White over yellow livery, and I think it was on an M plate, but didn't get a proper look. If I hadn't been driving someone to an appointment I'd have followed it to try to get a better look and possibly a photo. I know Bill's coach hire have a couple of S plate Volvo Olympian deckers, but I've not been aware of seeing a PS any time vaguely recently.

-

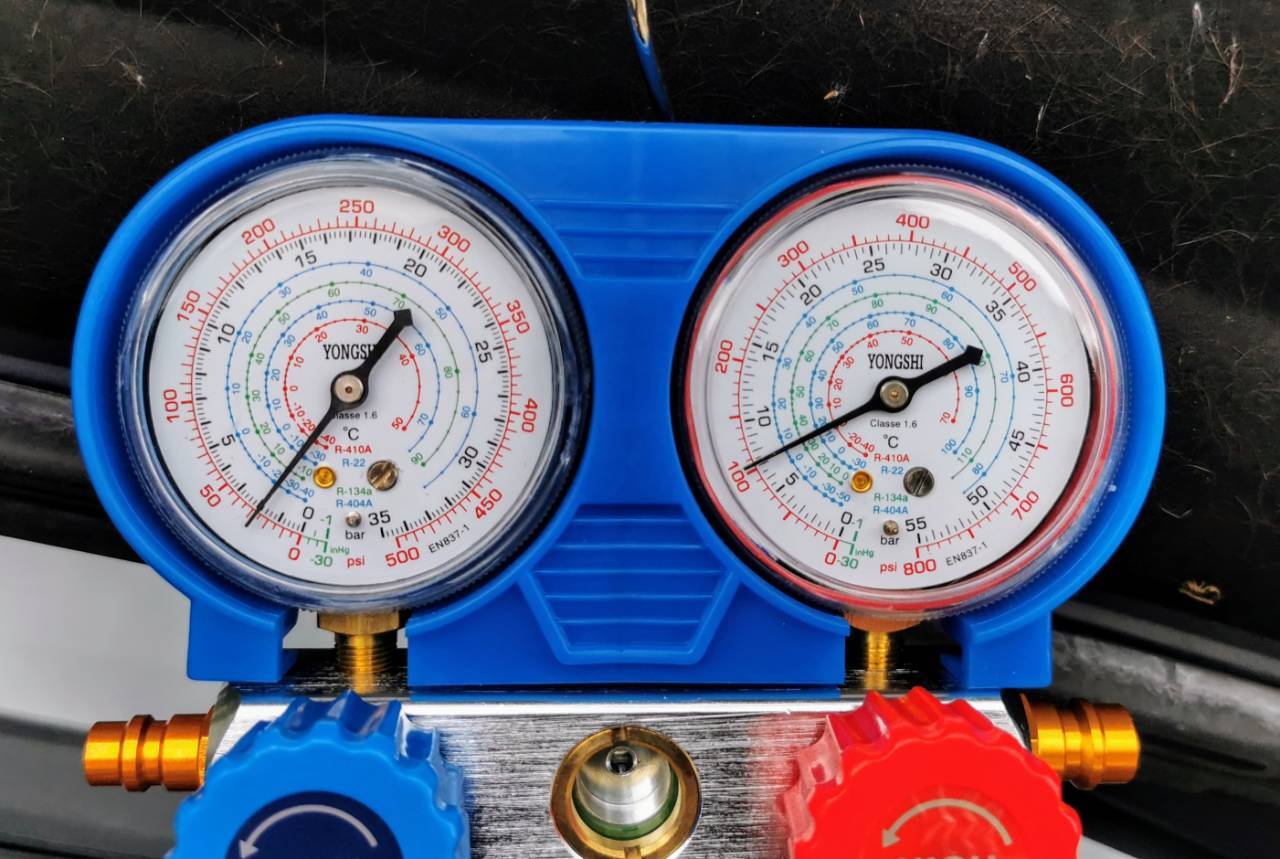

I've noticed that the AC in the Partner has started to get a little noisy. It's still functioning, but sounds to me like the expansion valve is feeding vapour which would suggest we're low on charge. Let's see what the gauges say. Disclaimer here: I used to help out a HVAC technician looking after a bunch of gear on and around the farm I used to live next door to - but I've zero formal training in the field, and what I have learned I'm rusty on to the tune of probably more than 20 years at this point! I can usually look at things and figure out roughly what's going on though. I do keep half pondering looking at getting certification in that field, as if you like hands on stuff it's great as it involves a bit of everything. Though sadly as with just about everything in life I find interesting or have an aptitude for I think I'm probably about 30 years late for the technology I'm happiest working on to be in mainstream use. Back on topic...Standing pressures first. Smidge under 60psi. Definitely a smidge on the low side, I'd be expecting to be seeing nearer 70-80 with the car being warm. Running (and stabilised). We're definitely short on gas. Low side isn't really too bad, but with an expansion valve throttling things that's kind of to be expected until the charge gets critically low. High side though tells the story, I'd be looking for probably somewhere in the region of 150psi even with how cool it is today. I was able to get the head pressure up a tiny bit by applying an artificial load by putting the system into recirculation mode with the heater on full, but it's definitely short on gas. You can't really fully diagnose a system like this purely with a simple set of gauges like this, even with a full set of temperature probes etc you're never going to be charging this by pressures. Correct procedure is to recover the charge then weigh the proper charge in (assuming it passes a vacuum test - ideally you'd pressurise the system with dry nitrogen and do a *proper* leak down test, but that takes time and I wish you luck finding a garage that will). So I'll be getting her in this week to get the system recharged.

-

If it's just a hose you need and it's a pig to get could you not just take the original to a hydraulics specialist and have them replicate it? Last time I did this was a transmission oil cooler line on a Saab 900, and the cost was considerably less than NOS parts went for.

-

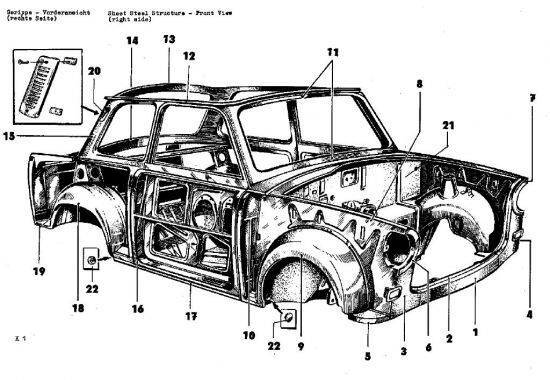

If you strip a Trabant of the Duroplast bits what you're left with looks remarkably like a miniature version of the base frame skeleton the Rover P6 is built around. Front and rear panels are non structural steel, I'm guessing simply because the moulding would be excessively complex to make in Duroplast with the various cutouts and such. The inner structure is a (surprisingly rigid) framework including the sills, floorplans, roof frame, window surrounds, front and rear wheel tubs, door apertures, front bulkhead, and boot floor. Everything else is then attached to that. P6: Source: http://www.roverp6parts.com/history.html Trabant: No idea where I originally found that one. Here's a (crap) photograph of one stripped to the shell which original surfaced on Pinterest somewhere. For such vastly different cars it's almost uncanny how similarly the very basics of the inner structure have been penned. P6 is obviously vastly more substantial, but you get the idea of what I'm saying.

-

Renewal offer has just landed from Hagerty for the Invacar, Rover P6 and Trabant. £244. Which I think is +/-50 of what it's always been for this policy irrespective of what vehicles are involved - the exception being the briefly present Merc W123 which brought with it a massive price hike. In contrast, the Partner is currently costing roughly £700 a year. Historically I've been the only user, though due to management nonsense one of my housemates now needs to do a 5 hour round trip to their Telford office once every three weeks to sit at a computer on a teams call to the same co-workers who are based at the opposite end of the country they do every other day from home every three weeks. Adding them as a named driver doesn't make a massive difference to the price, however 1st Central can only offer her business & commuting cover if I also add it for myself, then also adding them. Resulting quote? £2754 please. Haven't been able to find anything much cheaper elsewhere - so she's just buying short term insurance a day at a time for £15-30 a go as it works out considerably cheaper, which seems like madness.

-

Given they do have a bit of a reputation in that regard I'm under no illusions of things staying all that clean, but I'd like to scrub at least the worst of it off just so I can see if any new leaks do appear. The 'box just sweating a bit from seals and such that's deemed to be normal I don't have a problem with. For all it looks a right state I don't think I've ever been aware of this car leaving a drip of anything where it's parked (aside from water dripping out the interior before I sorted the bulkhead seal anyway), so it obviously isn't losing much. We did suffer a major technical failure today. Okay, that might be slightly overselling a blown tail light bulb. Needless to say this was a five minute fix. Really do need to get some paint on that rear panel. Also, aren't Nissan Qashqais huge? This car is still very much making me smile every time I see it.

-

Yeah, ours have done the same for years with the more expensive ones which I could kind of understand. Fact that the entire damned lighting section is behind the tills now just seems like total madness. How many hours of staff time does that waste them in a week? I really feel for the folks behind the tills too, they have a crap enough job as it is having to deal with the public, nevertheless now needing to find 3/4 of what they're asking for. Especially as a bunch of folks - like me - are probably already hacked off from having spent ten minutes walking round the store becoming increasingly convinced they're going blind as they can't find any of the general purpose spares anywhere now.

-

Don't just forget it. It's not beyond the realms of possibility that the other party may turn round and claim you scraped their car. It's worth reporting and getting the reference number in case someone pulls nonsense like that. My grump? Our local Halfords has always been a bit of a disaster. Nevertheless it is useful for random nonsense like bulbs that it's not worth making a 50 mile round trip to the decent motor factor I usually use down in Luton. They've just done a refit. Now *all* the bulbs, wipers, batteries, basically everything I'd be likely to go in for, is behind the counter. Which means you need to try to convey to whoever's behind the till exactly what you need. It took me a full ten minutes (much to the annoyance of the ever growing queue behind me) to get a couple of bloody tail light bulbs just now. Yes, I know a 10W festoon (265) bulb isn't a massively common one, but argh...it would have taken me 30 seconds to pick it out myself. Wasted a load of my time and theirs. Unsurprisingly, the queue at the tills has pretty much quadrupled since they changed things a couple of weeks ago. Used to usually off peak be a case of going in, grabbing what you needed and being out the door in less than five mins - which was basically the one redeeming feature. Not a chance now Oh well, their loss is Mileham's gain! Even if it will add to my fuel bill.

-

Yes, knowing there was enough in there was one reason I really wanted to change mine given this mess. Though having said that, it's never left a single drop where I park. Given the state of what came out though I'm very glad I did it anyway for the sake of the freewheel mechanism if nothing else. I do really want to get that cleaned up though just so I spot any future leaks if they do appear.

-

It's probably something worth having on the shelf anyway. I'll probably grab one when I next put an order through to Trabantwelt. Let me know if you'd like me to grab one for you as well given the postage costs. I do need to have a dig through the parts stash as well as I know there are at least *some* carb bits in there. Had the car out today and the carb definitely seems to be doing the job properly again. Gear change is definitely improved when fully up to temperature it feels like, and I think it may well be quieter at speed, though very hard to tell given how much noise there is from everything in general!

-

Happy to bring the petrol pressure washer along to a future FoD gathering (or on request) if it's useful.

-

Ah ha, you too then! Surprised and pleased really. It always felt like it was pretty much a collection of spares flying in close formation given it would never make any logical sense to restore given the value of P4s and the price of spares. Especially cosmetic stuff and trim, which that car really wanted a lot of, before even factoring in paint. Shame to lose the genuine patina, but it really did want the paint sorting to ensure the car didn't just decay rapidly if being used regularly. At the end of the day if it helps make sure it lives on it's all a good thing. Better this than stripped for parts or taking a quick trip round an oval.

-

Will give that a try. I definitely wouldn't be throwing the original one out anyway given I know a lot of people are very particular about originality on these cars, so it would always have been kept in a box in case someone wanted to use it for something later. Actually had a bit of a hiccup in the Trabant couple of days back. Was about a mile from home, came to a stop at a junction and found it bogged down when I applied throttle. Was able to coax things back into motion by adding choke, suggesting to me a fuelling issue. I immediately headed for home (which thankfully was mostly downhill so little engine power was needed) keeping the revs kept as low as possible. Knowing how quickly a lean condition can become catastrophic in an air cooled two stroke, this wasn't something I was taking chances with. Car was parked up and I grabbed the Partner to continue the tasks I was heading out for. I was working around other appointments at the time so didn't have time to immediately investigate. Later on I checked the screen in the fuel outlet at the tank (pretty clean), and confirmed there was good fuel flow to the carb. Next step was to pull the cover off the float bowl (which you can *just* do in situ), to confirm the needle and seat were working properly and to see if there was any crud in there. There was a little bit of sediment in the bottom of the bowl but nothing particularly major. What I don't know (and this does make me kind of wish I'd pulled the carb) was whether there was possibly a bit of water in there as that could definitely have explained it prior to me cleaning it out. With everything put back together normal service appears to have been resumed. I do need to actually look up a proper diagram for this carb anyway as I'd really like to turn the idle speed up a touch, it has always felt like it's a little on the slow side. Especially if you've got the lights on. Today I had another crack at changing the gearbox oil. I jacked the car up a bit this time to give me better access to the drain plug, and was successful in getting it removed this time. What came out both looked and smelled like absolutely ancient EP90. Which given that the correct HLP68 fluid is a light golden colour isn't great. Definitely well overdue a change either way. A little bit of swarf on the drain plug magnet, but nothing I'd not expect and certainly no chunks. Area around the filler was cleaned up to ensure no chunks of anything fell in during refilling. I really do need to go to town on this thing with the degreaser and pressure washer one day as the entire power plant of this car is a greasy slime ball at the moment. This is pretty common for these cars, but I'd like to get it all clean at least once so I've got half a chance to see where any new leaks are coming from in case they do need attention. Getting to the gearbox filler required me to remove both the hot and cold air ducts for the heater to make access easy as it's otherwise a bit buried. Have only been fora brief run out today, but it definitely feels like the gear change is cleaner, changing down into second in particular it feels like the sycro is having an easier time of things. Is it any quieter? Maybe? Still sounds like a tumble drier full of marbles at idle, but I get the impression that's not exactly unexpected.

-

I do love the instrument panel on the pre facelift Sierras. With the gigantic legends for the warning lights, not actually where the lights are...really not quite sure what they were thinking with that, but it was definitely distinctive. Aside from the seatbelt light as I recall...that is actually where the legend is isn't it?

-

What bloody drivel. It's a run from one end of the UK and back. Any reasonably roadworthy car should be capable of handling that. Trust the Sun to make 1000 miles sound like it's fully circumnavigating the earth!

-

Of course I approve, both because Saab and also become I'm all for there being more two stroke madness on here!

-

Dentist checkup. Oh look, I need yet another three fillings, and one of them is bloody huge. That will be two further visits and £400 please. Oh joy.

-

Ah, this again. Managed to end up with two cars with their MOT due within a couple of weeks. Not the best planning on my part. I need not have worried. Advisory for some rust on the offside sill, which is fair. It looks worse than it is. I think there's one nick in the stone chip that the water has got in through and has lifted it. No actual rot there yet as far as I can tell having poked it, but it will be stripped back, cleaned and re-painted, hopefully get that sorted for a while. I've also made the front end look at least 50% less shabby. Before: After: That delaminated and rust stained number plate had been bugging me since the day I bought the car. The rear one will involve taking the tailgate interior trim off to secure properly so that will wait till tomorrow. Said trim also rattles so I want to pull it anyway. Other small and utterly pointless job which will make it look massively disproportionately better will be cleaning up and re-painting the light guards, though I don't think they look as rough in photos as they do in person. Original plate of course didn't get binned. From that angle my garage almost doesn't look like a *total* disaster! The Rover's new washer pump arrived today and was fitted. Not exactly a difficult or exciting job. Which has restored a reliable washing function every time the knob is pressed. Actually gives a really decent mist across the screen, far better than on a bunch of far newer cars I've driven. Also for Dollywobbler's reference, yes the P6 has really good wiper overlap. Have also go hopefully everything I need to make one good mechanical fuel pump out of one and 3/4 bad ones now. Let's see how that goes.

-

I never quite understood why having the facilities to clean your windscreen was so common at fuel pumps in the US - right up until the first time I drove at night in the Mid West! Ah, so THAT is why it's so common. So...many...bugs...

-

It's a small world sometimes isn't it!

-

It's absolutely worth reporting it. Firstly if heaven forbid violence ever did result (not necessarily just to the neighbour), if there's prior history of threatening behaviour on file from this individual it makes the life of the police a lot easier to get things moving quickly and to help make any charges stick because it's not just a one off in incident. Also this sounds like the sort of crazy individual who they might already have their sights on but short of sufficient probable cause to actually intervene. A report of them threatening an elderly neighbour to the point they fear for their safety could well be exactly what they need to kick things off. Make absolutely sure though that if they at any point feel that they fear for their safety that they call 999 without delay.

-

Tail light surrounds now match. Have been to the post office today to see whether we could get the tax changed to historic, but as I had pretty much expected it looks like I'll need to contact the DVLA directly regarding that. The only date which their computer brings up is the 1999 import date, and there's no option available to them to change the tax class. Sure that will be a barrel of laughs to sort. Will need to wait until a day where I'm feeling particularly patient. The Trabant as of yesterday has now officially ticked over 1000 miles since arriving here in December. Edit: Front mud flaps have now also been fitted as I got tired of them getting in the way in the garage. Did find some crunchy bits in the underside of the offside sill which will definitely want remedial work before next winter. Looks like a very old patch which has reached the end of its useful life. Nothing that's imminently terrifying, but I suspect if my MOT tester had prodded the area I'd have been left with a hole to fix. Plus one drain hole is definitely bigger than the one on the other side of the car. On the plus side it's about as easy a repair as you could wish for so I'm really not bothered by having found it. Par for the course on a vehicle of this age which doesn't look like it's ever had anything beyond a couple of running repairs before, and will be properly sorted in due course.