-

Posts

7,283 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Posts posted by grogee

-

-

-

£675 Astra. How bad can it be? You do have to get it from Nuneaton though.

https://www.gumtree.com/p/cars-vans-motorbikes/2005-vauxhall-astra-estate/1477843874

-

Just done my bins. I thought of @sierraman. It's a four-binner tomorrow as well

- egg, sierraman and GrumpiusMaximus

-

1

1

-

2

2

-

I've checked block and there is no apparent banana-ing that I can detect. However there is pitting on areas of the block around the coolant channels, but not near the rings which seal the combustion chambers. There is no way of getting rid of this without a mill and a fly cutter so I'm going to live with it.

I have been On A Journey as far as O-Series family tree is concerned. I was blithely assuming that all blocks and heads were basically the same, and I've successfully ordered parts for other cars (eg Rover 2000 and Freight Rover manifold gaskets) that fit just fine.

Delving a little deeper I have found that head gaskets differ, at least between FWD and RWD cars and possibly even between FWD car derivatives.

Part of my previous HG woes may well have been because I've been trying to fit the wrong gasket.

The gasket in the plastic film is for a Sherpa/LDV and you can see the oil way and coolant channels don't match up.

Fortunately I have a gasket listed for MG Maestro and Rover 800 (bASe models of which used O-series) coming.

Whisper it, but I've also smeared a bit of sealant around the block where the pitting is apparent. This is a big Haynes no-no and must not ever be done under any circumstances.

I wonder if it'll work?

-

9 hours ago, SEATMad said:

"They were certainly a desirable dual purpose vehicle favoured by business men who perhaps had a slightly practical aspect to their work. It meant that they could get on site purportedly on the basis of doing a delivery without the formalities of going through the induction process."

-

13 hours ago, Tommyboy12 said:

The other thing to check when you take the head off is the flatness of the block. It's fairly rare but not uncommon to have an uneven block face.

I get this, but it's nearly impossible to get my eyes level with the block to see if there's daylight under a straight edge.

Also, if the block isn't flat, I won't like that answer.

-

@mercedade the head that was misbehaving was NOS, but I got it skimmed and ported. To no avail it seems as it's running like a bag of shite with no compression.

Today I've been building the old head back up, yesterday was grinding in the valve seats which took some effort because the exhaust ones were quite pitted.

Also yesterday I plugged a stud hole that I'd accidentally drilled into the coolant channel. It was a bit of a head scratcher how to plug it, because there was no access to the inside of the coolant channel.

In the end I did this: found a bolt of the right depth. Mixed up JB weld and smeared it into the hole. Screwed bolt into head, pushing the JB weld back to where it needed to be to seal the hole. Then tipped head sideways so the JB weld was drawn down by gravity to sit on the bolt.

Bit of a brave moment this morning when I came to undo it but it's worked really well.

I could have used the new valves from the new head but I've still got hope that I can get it running right somehow, so I'd like the new valves to stay with it.

I'm now at a point where I'm ready to check the Clarences again, so that'll be tomorrow's job.

-

11 hours ago, Schaefft said:

500 quid 2.0 Turbo XM Estate. Doesn't run because the seller not knowing the keypad code.

This guy is very skilled. Seems like a really nice guy too. Here he is 'cracking' the code for an XM keypad:

- colino and EyesWeldedShut

-

2

2

-

14 hours ago, Oi_Oi_Savaloy said:

I spent alot of time in the vicinity of the Lotus this weekend. I say vicinity because I was no more than 4 foot away from it for quite alot of saturday and sunday..............but much of it was spent thinking about the jobs that need to be done rather than actually doing them.

I'm a natural procrastinator (plus an absolute pessimist for most the time) at the best of times but what really hit me this weekend is that my friend, a mechanic (and a really good on at that) isn't going to realistically be able to help me with the car.

He's got too much on his own plate (wife has been v ill, now better, but still isn't and never will be, back to 100%) and he's got his own life you know? He's got sh*t going on that I won't speak about on here but he'd help if he could.

Trouble is, in my own mind, I'd been falling back on him (he'll sort that, or he'll know what to do there, or he'll have a shortcut/know exactly how to do that job) so I hadn't been putting as much thought into the car as I should have been.

I'm not a mechanic..........and I grew up with a dad that did all the jobs on the car, without wanting me around (slowed him down!). I've always been into cars however..........but practical experience? None really. I know the theory, and I'm mechanically sympathetic....................but actually doing the complicated stuff? It takes me ages to work through a job, before actually tackling it. Part of the fear is getting it wrong. And then having to buy more parts to fix it. I just can't afford to do that right now. Once I get a job, the pressure of that element will lessen, and speed will pick up.

It's the realisation that I'm on my own on the job that is the Lotus tbh, that has hit me.

I've got to get on and fix it and I guess the satisfaction will be immense when I do sort it..................but in all honesty I'd rather have the help and know that the car is sorted (because he's worked on it).

I've got to get on though.

So I spent alot of time working out when I'm going to tackle the various outstanding jobs, and in what order.

The priority is to make sure the engine works (we know it did 3 years ago) but it's been sat here for that time and............if it doesn't, there's no point tackling the door (frame needs changing) and other interior bits, if the engine doesn't work.

So this weekend I put the tank back in, sorted out the new fuel pump (needed bits transferring over from the old one, which I'd kept, thank god) and making sure I had all the bits for some of the ancillaries on the engine (they'd been taken off by my friend and put safely away.......so safely in fact I'd forgotten where..........found now..........they were in an awkward safe place........not using it again!)

I've just got to hook everything up back there in the boot (I'd not done this bit thinking mechanic friend would be over to tell me if I needed to put some of the white plumbers string (?) around the fuel pipe connectors to help stop leaks etc etc (a small thing, but again it slows things down as I have to think about that, whereas mechanic friend just knows. It's a minor thing.........but the thinking time adds up to quite an amount as each job I tackle takes up unnecessary thinking time.......) and then I can move on to fitting the waterpump...........and putting the dash back together temporarily and then it should be ready to fire (I'll run the engine for a minute or so - it's not going to overheat) before I put the radiator and fans back in (needs a bit of fettling that - not an easy job at all). And it's heavy as a package too).

Onwards! (with slight trepidation).

Been thinking about this post all day.

Yes it's useful to have a skilled mate who can rescue jobs and provide advice on tap.

But... Learning is failing. Failing is learning. He will have learned from his mistakes and you can, too. God knows I have.

I worked in a garage aged 14-21 in an apprentice type role, weekends and holidays in between studying. My mentor was incredibly patient and a good teacher.

Then I moved away and for a long time I was paying Other People to fix my cars. Usually it was expensive and afterwards I'd always find stuff wrong or something that I didn't like.

In the last ten years or so I've increasingly taken on jobs myself. Usually justified by the cost of the required parts and tools being less than the cost of a garage job.

Sometimes, I get it wrong and break stuff. Sometimes I have to do it twice. Each time this happens, I learn stuff.

My point being: don't be afraid to fail. You've got work to do on this Excel, maybe it would be easier to learn on an old Escort but this is the path you've chosen. The Excel will bite you I'm sure, it's old and British and that's just what happens. But almost everything can be sourced and replaced if needed.

Strip a thread - drill it and tap a bigger one. Learn how to tap at the same time. Fixed, and now you aren't scared the next time you strip something.

Also I'm certain the Excel isn't your daily driver. This is important, because failure doesn't jeopardise your ability to get to work or whatever. Failure would mean a setback but not an unrecoverable disaster.

All of this to say - more power to your elbow. You can do it! Get stuck in and you have the hive mind here to ask if you get stuck.

(Cautionary note: don't listen to my advice. I'm changing my Maestro head gasket for the fifth time, so I must be completely incompetent).

-

OK so I'm halfway through removing the Maestro head (for what is possibly the fifth time).

As others have commented on this thread:

It could be warped head (even though it was freshly skimmed), bad valve sealing or yet another bad gasket. Either way the cylinder compressions are all sub-par so I'm going to revert back to old head for the sake of having a running car.

I contacted Rimmer Bros about my genuine Rover gasket ordered in Feb, got a less than helpful reply. Twats.

Anyway once it's off it may be more apparent what's wrong, I'll go back to SC Porting and ask for their advice.

Curiouser and curiouser. And fucking annoying.

-

OMG this Maestro saga never ends.

I previously reported a misfire, and assumed I had ignition troubles. But after changing plugs and leads the lumpy running was still apparent.

No. 2 cyl looked suspect with a noticeably sootier plug than the rest.

Anyway I went round in circles for a bit including checking the injectors, and reached the conclusion it was getting fuel and a spark.

Luckily @Cluffy has a compression tester in his Stores so I rigged that up, cable tied the throttle open, pulled the fuel pump relay and gave it a few cranks on the starter.

Compression ranges from poor to pathetic. Something isn't right. With the original head I was getting 130psi pretty consistently.

I'm going to revert back to the original head just so I've got a functioning car, then I can explore the causes a bit further. All quite frustrating, what with all my careful valve grinding and valve shim faffing.

It could be that the valves aren't properly lapped. Rightly or wrongly I used the drill method - sucker stick in drill, move the valve up occasionally, then reverse direction and repeat. I ended up with a semi-decent matt grey valve face which I thought was OK, but perhaps it isn't.

- Dyslexic Viking, JMotor and Tommyboy12

-

3

3

-

-

1 hour ago, SEATMad said:

Don't forget to tag @eddyramrod, it's the law.

That is one tidy looking CF and it's cooler than pre-facelift because I said so

- eddyramrod, SEATMad and egg

-

2

2

-

1

1

-

So where does the Monza fit into this?

We take the piss out of BL product overlap but late 70s Vauxhall/Opel was bonkers.

-

Wow. I wouldn't know where to start. It looks very crispy

-

Sorry, but these people @wuvvum and @sierraman 's brother are surely winning at life?

Escort to Allegro VDP = win. You'd be beating the girls off with a shitty stick. "Can I try out the picnic tables, oh PLEEAAASE"

Escort to Lada = win. You've gone from decadent Western frippery to robust Eastern common sense. You're advertising your socialist credentials and again, the knicker elastic should be snapping on every street corner.

-

-

I managed to bolt it all back together and then fired it up... Disaster. Oil was leaking out of the feed to the turbo bearing. Initially I thought I must have left a crush washer out from the banjo bolt, but on closer inspection it was there. I had torqued it to factory spec seeing as it was a semi-important fixing.

In the end I just did it up tighter which has sealed it thank God.

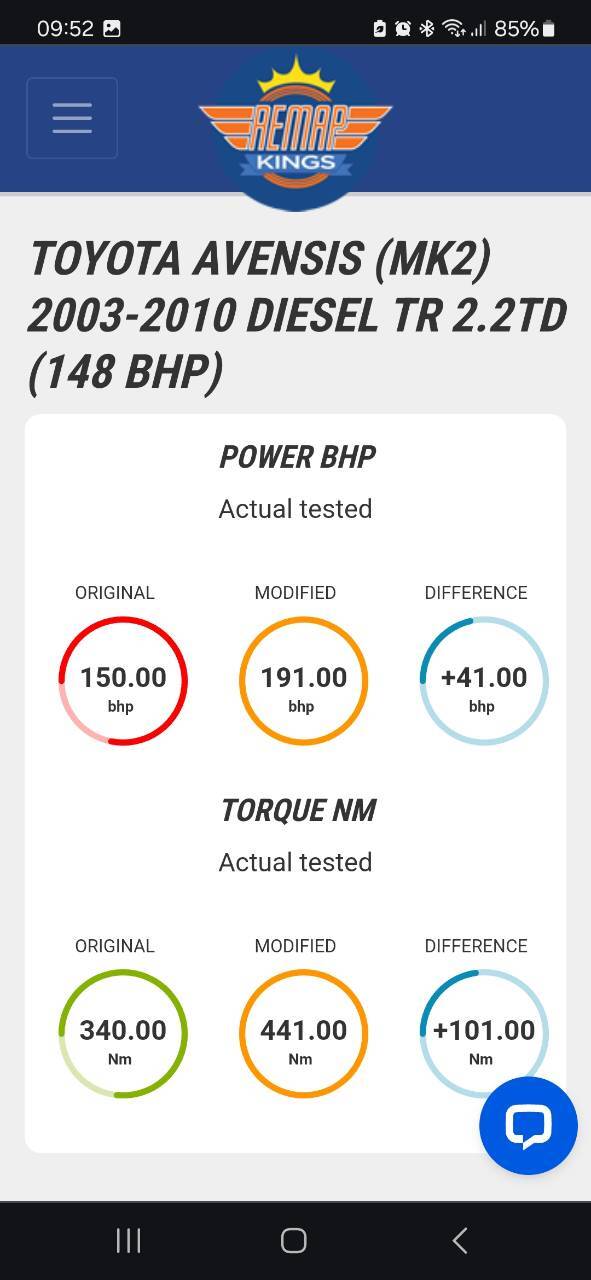

Went for a drive which confirmed it now GLF, however...

Previously I'd fitted one of those Chinese fuel pressure sensor things that fools the ECU into thinking the fuel pressure is lower than it really is = cheap performance upgrade.

On my test drive I booted it out of a junction then felt the dreaded jolt as it decided to engage limp mode... It actually cut out completely but I managed to turn into a side road and I had my diagnostic reader with me.

Read the code which was something like 'Major fuel leak detected' so I thought I might have chafed a hose when I moved the fuel filter to one side for access. But no leaks and no diesel smell.

I think what happened is the fuel flow rate and/or pressure difference was outside of the set limits thanks to the Chinese cheater device. I reset the code and it ran fine to get me home, so I removed the Chinese kit and have reverted back to standard.

I really thought I'd broken something serious but it was the nannying ECU detecting Fun Outside Specified Limits.

Last night I drove to Reading and back to go into London and watch a gig, the car performed faultlessly and averaged 53 mpg so I'm pleased with the fix.

If spending money allows I'll be looking to get a proper remap as there is more performance to be had for sure.

-

-

Forgot to mention there is a second 'service position' for the bonnet which opens it wider for better access to the backside of the engine.

Access is still dreadful though, and I've had to use all the tricks to move the fixings under the turbo. Also even if you can get your hand/arm onto a ratchet, I'm in such an awkward position that I can't get any purchase on it.

Despite all this I have birthed a turbo. Just having a lunch break now but I did get pretty confused about one of the turbo oil drain pipe nuts, I was totally flummoxed about why it wouldn't thread onto the stud. See if you can guess why...

- JMotor and Dyslexic Viking

-

2

2

-

Has anyone said this is sterling work yet? If not, I will.

Your patience with the filler neck is incredible, well done. I think when the time comes on the Maestro I'll be using some combination of aluminium tube and fuel-friendly silicone/rubber hoses.

-

Be like sister Grogee. £650 Smellihull. Engine light is on, a bit of black electrical tape should fix* that.

https://www.gumtree.io/p/cars-vans-motorbikes/2003-vauxhaul-astra-16/1477320380

-

My plan worked, unbelievably. Propping the car up about 6" higher gave me room to get the big ugga dugga under the car, and with a couple of extensions I was able to undo the turbo to manifold nuts which are generally tighter than a council pothole budget.

I can't help but think it's no coincidence that I was able to route the extensions through the only gap in the underbody between the subframe and gearbox. I get the feeling Toyota takes servicing pretty seriously. I mean this isn't an easy job (it's still not finished) but you can see where provision has been made for tool access.

I've still got to undo some coolant hoses that pass over the top of the turbo. I think this is a bit of a bodge by Toyota, on some models the turbo is water cooled but not on mine, so a bypass is routed over the top of it.

I think I'll lose a bit of coolant but it's quite high up so hopefully not loads.

I would have done it this afternoon but the gusty wind was really pissing me off.

-

I've been driving the Avensis around Lincs all weekend and while it's been mostly fine the lack of turbo oomph has been fucking me off so after I'd unpacked I jacked

offit up and commenced battle with the turbot.Access is pretty shit really, I'm sure modernz are worse but I was having to be creative with tools to undo the (15 year old) exhaust fixings.

However we're now at the point where I can begin to try and unbolt the fecker from the manifold. It's released from the cat so that's a good step forward.

Two of the turbo to manifold fixings are only accessible from underneath, and the gearbox and subframe obscure the line of sight to them so again I'll need some luck in getting it shifted.

I think I'm going to jack it a bit higher, put it back on stands then I've got a bit of room to get an impact and selection of extensions on, hopefully they'll shift it.

.webp.d9813579d0c95bcca3a46e6840c5cb69.webp)

.jpeg.8722fc1c6658989f0db8ea1ce9dd29b0.jpeg)

1987 Lotus Excel SE

in AutoShite

Posted

Pipes - rightly or wrongly my technique is to poke something sharp (eg pick or small screwdriver) in between pipe and spigot, then lever it open enough that you can get a WD40 or GT85 aerosol straw in there and squirt some in. Then more wrestling and swearing until it comes off.

Gaskets - yeah don't worry ours are all the same. For bolt holes I sometimes make a cross 'X' cut rather than cut a proper hole, or do a square, or use a paper hole punch.